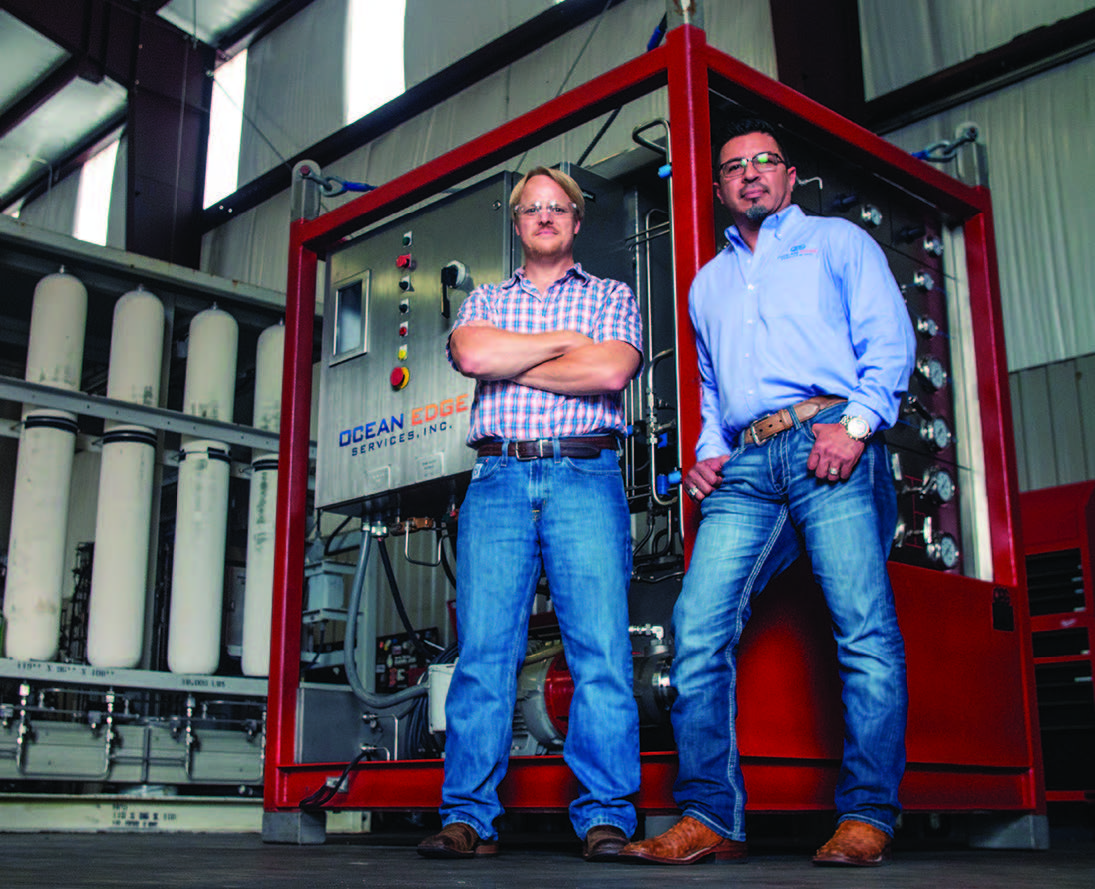

(Pictured from l to r: Swagelok Southeast Texas’ Chris Ori and Chris Jones, and Ci’s Matthew Macaluso)

Do you ever consider your company, operation and responsibilities and think "What if I had access to experts who could increase my production speed?" If you did, what could you accomplish?

Do any of these other issues sound familiar?

- "I could use assistance with forecasting."

- "I wish I had help with supply chain management."

- "I need a second set of eyes ensuring reliability."

- "I wish I had access to certified engineers."

They sound familiar to Swagelok Southeast Texas, because our clients have relayed those concerns to us for years. And we've been listening. Charbonneau Industries is just one example of how we were able to provide help in those areas, and fuel growth.

Charbonneau Industries responding to needs of customers pays off

Charbonneau Industries, or Ci, is a brand-neutral master distributor and integrated supplier of engineered products and services. Its focus on quality and responsiveness through a unique stocking strategy has propelled the company’s growth.

Located in Houston, Texas among a network of the most critical gas pipeline infrastructure on the planet, Charbonneau Industries (Ci)’s Matthew Macaluso, Mechanical Engineer for Ci, describes what they do. “Think about your house and anything in it that runs off of natural gas. There is a vast network of pipelines that need to be kept safe and running at all times. At Ci we provide full packages, not only valves, but entire assemblies that help with integration and automation, and keep those lines working optimally.”