Safety Training & Education

Build Your Team’s Expertise Fast

Whether you’re onboarding new employees, maintaining safety standards, or filling the knowledge gaps within your workforce, Swagelok Southeast Texas is committed to providing you with hands-on training solutions that align with your specific needs and concerns.

Our training courses range from safety-focused programs such as tube fitting installation, safe selection and inspection to technical offerings like Sample System Training. Our training sessions are led by experienced, Swagelok-certified experts in our state-of-the-art training facilities or at your site.

Meet our Trainer

Steve Willborg

Steve has 32 years of Swagelok experience serving as technical advisor, market specialist and Swagelok certified installer. He has supported fluid handling applications in a variety of environments across southeast Texas including OEM sites, research facilities, the Texas medical center, compressor stations, pilot plants and refineries – upstream and downstream. In his current role as Swagelok certified trainer he enjoys helping local industry close the middle skills gap.

Swagelok Comprehensive Safety Training

Safety is our top priority. Well-trained associates are valuable assets that can increase productivity and safety in your workplace, saving you both time and money.

To register for training online complete a Sign Up form, contact your Technical Advisor or call any of our locations for Training Services.

Watch our Swaging with Gary episode to hear about how a customer shutdown could have been prevented with Swagelok proactive training.

Training Features

- Experienced, Swagelok Certified Trainers

- State-of-the-art training facilities

- Training classes that range from 4-8 hours

- Ability to custom build a full day training class that best suits the need of your company

- Option to design and implement long-term learning plans for your team

Customer Benefits

- Fluency with the proper application and installation of critical fluid system components

- A better understanding of your team’s role and responsibilities regarding safety

- Awareness of with the potential hazards associated with pressurized fluid systems

- Certificate of Completion that meets the requirements of many owner companies

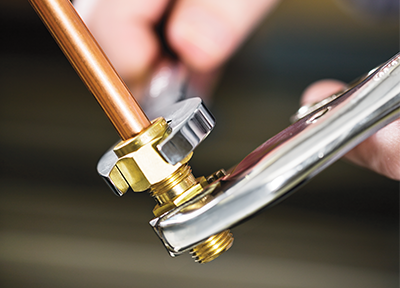

Tube Fitting Installation & Tube Bending

8 Hours (Available as separate 4-hour classes)

Discover how to optimize your fluid system and minimize leakage with proper fitting installation and tube bending techniques. This course is designed to help you reduce rework costs, scrap, downtime and increase safety in the workplace.

Upon course completion, students will:

- Demonstrate foundational tube fitting knowledge to minimize risk of leakage and ensure system integrity

- Know how to properly select, cut and deburr tubing, correctly assemble a tube fitting along with proper use of Swagelok gap inspection gauge

- Make basic bends and understand how improper bends affect fitting performance

- Overview of thread types and proper installation of threaded connections

Advanced Tube Fitting & Inspection

4 Hours

Identifying an improperly installed fitting or bend defect can mean the difference between a sound fluid system and a shutdown. Learn how to stop leaks and blowouts before they happen through proper inspection.

Upon course completion, students will:

- Understand the mechanics of how a tube fitting works

- Identify variables that cause fittings to leak or fail and understand the different types of leaks

- Identify tube fittings components and understand their importance to proper assembly

- Point out common tube bending defects and understand how they impact fluid system reliability

- Identify the different types of threads through design and markings

- Inspect installed fittings and determine if they are reusable or not

Medium and High-Pressure Cone & Thread Installation

4 Hours

Consistent performance, especially in critical applications, is important to a successful system. This course offers foundational knowledge in cone and thread preparation and installation tailored to bring optimal performance to your medium or high-pressure system.

Upon course completion, students will:

- List safety precautions when using the coning and threading tools

- Describe medium and high-pressure fittings and differentiate the components of each

- Proper use of the coning and threading tool including tube

- preparation, inspection and maintenance

- Install cone and thread fittings

- Perform basic troubleshooting

Safe Valve Selection

2 - 4 Hours

Understand the valve selection process to get the right valve for your application to optimize performance and increase safety. Depending on job responsibilities, this session can be tailored to provide a basic understanding of valve selection to taking a deeper dive with engineers and designers that spec valves into fluid systems.

Upon course completion, students will have an understanding of:

- The five valve functions

- Process of selecting the correct valve for your application

- Materials of construction and system compatibility

- Compliance with specs and codes

- Actuator options

Pressure Relief Devices

4 Hours

This session provides an overview of products designed for overpressure and excess flow protection. Proportional relief valves, rupture discs, check/relief valves, as well as excess flow valves are covered. All attendees will participate in a workshop which includes “hands on” exercises.

Upon course completion, students will have an understanding of:

- Set pressure versus reseal pressure

- Performance variables

- Lock wire and tagging

- Trouble shooting

- Valve maintenance

Regulator Safety

2 Hours

Learn the basic functionality and safe operation of pressure reducing and back-pressure regulators to minimize risks and

Upon course completion, students will have an understanding of:

- Materials of construction

- Pressure control range

- Resolution & control

- Vent options

- Performance variables including SPE, droop and creep

Thread and End Connection Identification

2 Hours

Engaging incompatible threaded connections results in damaged ports, inoperable equipment, leaks, and downtime. This session covers the step-by-step identification procedure for thread types to ensure safe and reliable system operation.

Upon course completion, students will have an understanding of:

- Thread and end connection standards

- Proper use of pitch gauge, calipers and reference tables

- Determine the difference between tapered and parallel threads

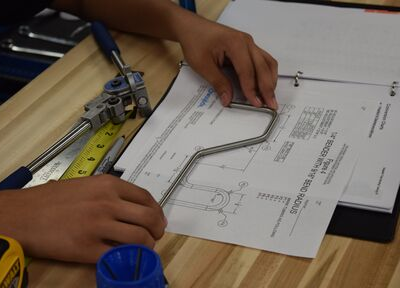

Orbital Welding

4 Hours

With plenty of hands-on instruction, participants learn orbital welding principles, plus how to set up, run and troubleshoot an orbital welding system. Our instructor is a Certified Weld Inspector (CWI) and Certified Weld Educator (CWE) qualifications, as well as at least five years of experience in orbital welding instruction.

Sampling System Courses

These courses are led by instructors who are experts at designing, installing, and maintaining sampling systems.

Process Analyzer Sampling System Training (PASS)

June 24-28, 2024

In this five day course, you will learn how to design, optimize, and build process analyzer sampling systems that deliver timely and accurate results with the design principles needed to prevent costly sampling errors. Course content is derived from Industrial Sampling Systems, a technical reference book authored by industry expert and consultant Tony Waters.

You will study how to:

- Recognize and diagnose sample transport problems

- Calculate pressure drop in a fast loop or return line

- Prevent or control phase separation

- Read and create sampling system schematics

- Design and build your own sampling system

CLASS FULL

Process Analyzer Sampling System (PASS) Subsystems Training

No classes scheduled at this time.

This course breaks down design elements of industrial sample systems into subsystems then further separates them into discrete function blocks. Through an effective blend of lecture, class exercises, and a team design project delivered in a small class environment, you learn how to assemble these function blocks into complete system designs or employ them as analytical tools to assess and improve in-service systems.

You will study how to:

Sample System Problem Solving & Maintenance Training (SSM)

July 10-11, 2024

Specially developed for anyone involved in the maintenance of process analyzer sampling systems, this course will show you how to recognize and diagnose common sampling system design flaws. You will learn how to employ formulas, calculations, and engineering principles and, in the end, you will put your new found knowledge to the test and troubleshoot actual system designs.

You will study how to:

- Identify when time delay is an operational problem

- Calculate and optimize sample transport lag (time delay) for liquids and gases

- Recognize and understand deadlegs in a sampling system

- Select and maintain sample system hardware

- Detect sample transport problems

- Troubleshoot and improve existing sample system designs

- Understand the ownership cycle of sampling systems

- Maintenance practices

You are leaving the Swagelok Southeast Texas site for the Swagelok corporate site.

For additional assistance, please contact your local Swagelok Distributor at 281-422-3533.

You are leaving the Swagelok Southeast Texas site for the Swagelok corporate site.

For additional assistance, please contact your local Swagelok Distributor at 281-422-3533.