Gas Distribution Systems

Achieving Peak Uptime Starts at the Gas Bottle

Swagelok gas distribution systems are designed based on best practices and can be built in many configurations to suit the needs of your application. We build standardized, configurable gas delivery systems to help protect system operators, increase process uptime, and improve process accuracy and repeatability. Our advisors, in collaboration with your team, will deliver a fully engineered system that is:

Modular Gas Distribution Subsystems

To effectively deliver gases from a high-pressure source to the rest of the facility at the pressure and flow rate required by each application, systems are built around one or a series of pressure regulation steps and may include four typical subsystems:

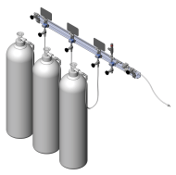

Swagelok Source Inlet (SSI)

Swagelok Source Inlet (SSI)

The source inlet establishes a connection between the high-pressure gas source and the distribution system. It's important the inlet is built with appropriate cylinder connections, hoses, tubing, filters, and vent, purge, and relief functions to ensure that gas can be safely fed into the primary gas pressure control or automatic changeover. For a single gas cylinder, the assembly can be as simple as a hose and connector, while multiple cylinders may require a manifold incorporating many hoses and valves.

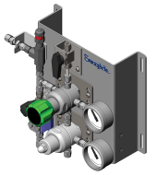

Swagelok Gas Panel (SGP)

Swagelok Gas Panel (SGP)

As the primary gas pressure control, the SGP completes the first pressure reduction of the source gas and ensures it is delivered at the correct flow rate to the next stage of the system. Pressure reduction is accomplished in either one stage with a single pressure regulator or two stages through a dual pressure regulator arrangement.

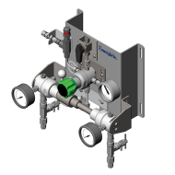

Swagelok Changeover (SCO)

Swagelok Changeover (SCO)

The automatic changeover system seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. Our changeover station allows for custom changeover set points to help reduce wasted gas left in cylinders.

Swagelok Point-of-Use (SPU)

Swagelok Point-of-Use (SPU)

The point-of-use system provides the critical last stage of pressure control prior to the gas being used. These are often the least complex of the four main subsystems, typically having a pressure regulator, gauge, and isolation valve. Point-of-use systems give operators and technicians a convenient and accurate method of adjusting pressure to meet their test bench or equipment needs.

Swagelok® Gas Distribution Evaluation and Advisory Services

On-site Evaluation and Troubleshooting

Our engineers provide critical analysis to inform proper regulator selection, identify system upgrades, and guide the design and assembly of standard and customized solutions. Following a thorough assessment of your gas delivery systems, you will receive a full report that documents among other considerations:

- System performance and fitness for function of existing componentry

- Required vs. actual flow rates

- Compressed gas leaks and the money that is lost

- Safety, environmental, and reliability scoring for each system

- Areas for improvement and suggestions for suitable solutions

- Recommendations to help maximize gas bottle usage