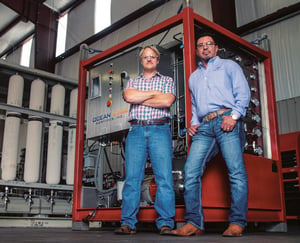

When Swagelok Company’s FKB series ball valve was first released, an oil and gas industry customer possessing decades of experience with our products—Santiago “Chili” Gomez, founder and president of Ocean Edge Services, Inc. (OES), in Houston—tried to make it fail. He pushed the product to its limits. It would not fail.

Chili was battle-testing the Swagelok component because he was thinking of putting it to use in a high-pressure subsea application where failure was not an option. Swagelok came through for him—once again—and he standardized on the product. Chili’s razor focus on quality is rooted in his desire to always deliver safe and reliable solutions for customers. “Every project has your name on it,” Chili reflected. Fast forward to today. Chili is about six years into his own venture after devoting 20-plus years of his career to global product and services companies in the oil, gas, and process industries.

OES has established itself as a leader in the subsea hydraulic controls sector of the oil and gas industry, providing producers, OEM providers, and consulting contractors with hydraulic power units (HPUs), tubing services, specialized welding, subsea distribution controls, engineering, and technical service.

“I’ve had the opportunity to watch OES grow from a startup company to where they are today, a key resource and leader among HPU manufacturing companies,” offered Chris Ori, a technical advisor with Swagelok Southeast Texas. “From day one, OES has been committed to building the ‘Cadillac’ of HPUs. They demand the best and produce the best.”

OES incorporates a range of Swagelok products in its HPUs, including FKB series ball valves; Swagelok tube and pipe fittings; ball, needle, and check valves; FK series ball valves and fittings; IPT series needle, check, and ball valves; IPT series fittings; medium- and high-pressure tubing; as well as cone and threading tools.

HIGH PRESSURES, HIGH STAKES

OES HPUs use 20,000 to 60,000 psi to force the hydraulic actuation of equipment from the topside of oil and gas platforms to the sea floor. Typically, the deeper the sea floor, the higher the required operating pressure.

“Quality and reliability are critical to OES’s customer base because high operating pressures create an extremely volatile environment,” Chris noted. “Safety is everyone’s top concern and failure in this setting is, quite frankly, not an option.”

OES’s pressure to deliver goes beyond equipment performance. Responsiveness in the offshore market—including product availability—can make or break a company or reputation. “We’ve been asked on multiple occasions by offshore platforms—sometimes at night—to replace another OEM’s failing HPU and integrate our HPU to keep the asset flowing,” Chili said. “Maintaining the flow and production of oil and gas is crucial to our clients. We make it our goal to help them maximize their return on investment, no matter when the request is made.”

Swagelok Southeast Texas collaborates with OES on long-term maintenance plans and stocking strategies designed to address any emergency situation. “When specific parts have not been available on tight timelines,” Chris recalled, “we’ve provided two- or three-piece solutions to meet specific needs.”

When he considers the future and the promising uptick in oil and gas industry activity, Chili envisions a continuation of his close relationship with Swagelok. “I trust Swagelok because we both strive to produce the safest and most reliable products for our customers. You make it clear to me every day that you’re invested in my success. That’s unique in today’s world, and for OES, it’s a competitive advantage.”