Downstream Application Solutions

Services and Products Designed to Serve the Specific Needs of the Downstream Market

Whether you need help diagnosing system performance, training for new team members or an outsourced assembly fabrication partner, Swagelok Southeast Texas has a team of experts dedicated to helping you maximize your plant’s uptime, improve safety and efficiency, and reduce costs.

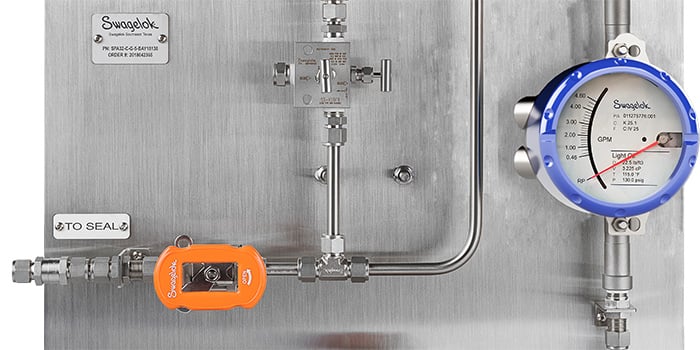

Mechanical Seal Support Systems

Designed to streamline installation and maintenance and maximize your uptime while saving on labor costs, Swagelok Mechanical Seal Support Systems are fully assembled locally to meet your specific needs.

- Configurable Plans that are API 682 Compliant

- Fewer Leak Points for Increased Reliability

- Expert, Local Support

Grab Sample Systems

Our Grab Sample Systems are customizable to allow for safe, efficient sample capture and maintain the integrity of your existing process. Plus, local support ensures fast, dependable expert service

- Grab Sample Module (GSM)

- Liquid-Only Sample System (GSL)

- Customized Grab Sample Systems

Application and System Specific Training

Our hands-on training courses range from safety-focused programs such as tube fitting safety installation and inspection to technical offerings like Process Analyzer Sampling System and Sample System Problem-Solving and Maintenance Training. Our training sessions are led by experienced, Swagelok-certified experts in our state-of-the-art training facilities.

- Swagelok Comprehensive Safety Training

- Tube Fitting Installation & Tube Bending

- Advanced Tube Fitting & Inspection

- Process Analyzer Sampling System Training (PASS)

- Process Analyzer Sampling System (PASS) Subsystems Training

- Sample System Problem Solving & Maintenance Training (SSM)

- Medium/High-Pressure Cone & Thread Installation

- Orbital Welding

- Safe Valve Selection (4 hours)

- Pressure Relief Devices (4 hours)

- Regulator Safety (2 hours)

- Thread and End Connection Identification (2 hours)

Field Engineering

Our Swagelok field engineers are a dedicated team selected for their expertise in fluid systems. They evaluate and diagnose problems within your analytical and grab sampling systems and provide solutions through design optimization, and recommending the right components and materials for your application.