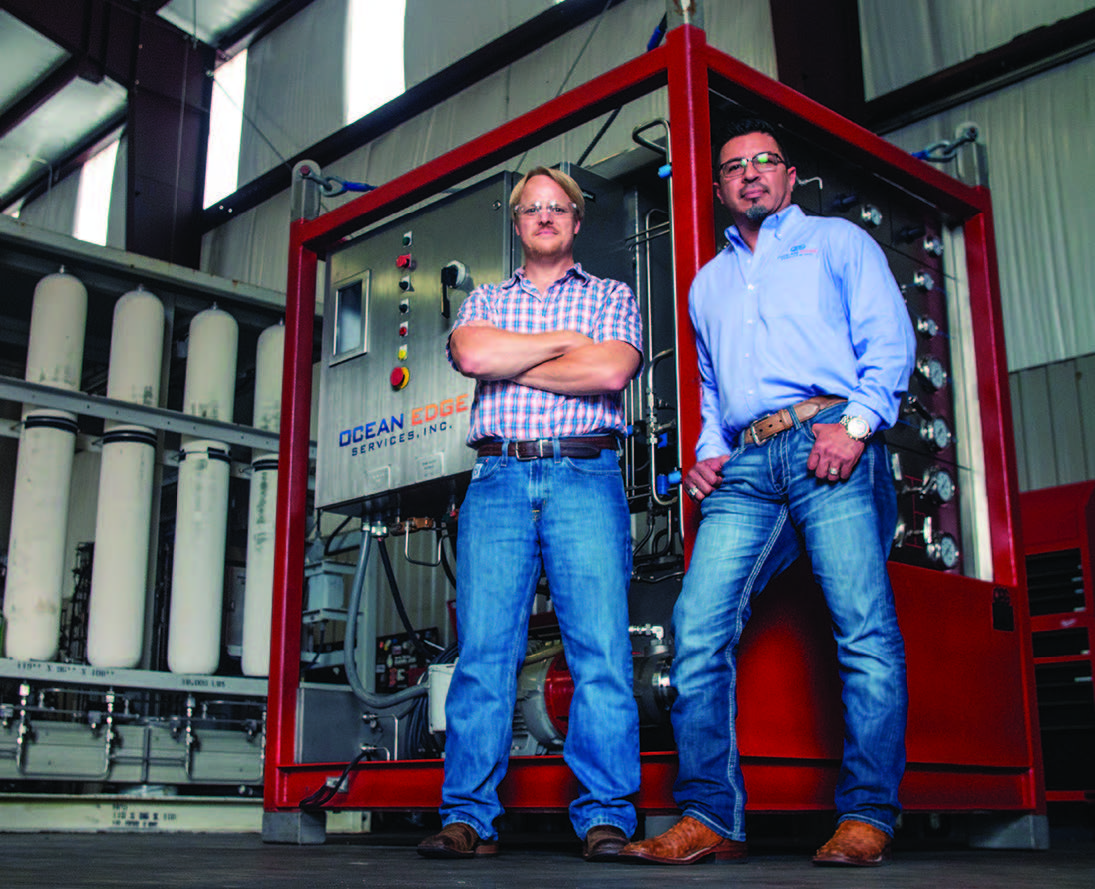

Watch this episode of Swaging With Gary as he gives you the straight facts and covers important issues regarding tube fitting Intermix and Interchange.

Intermix is any combination of nuts, ferrules and bodies. Interchange is using the same brand of nut and ferrules with another brand of body.

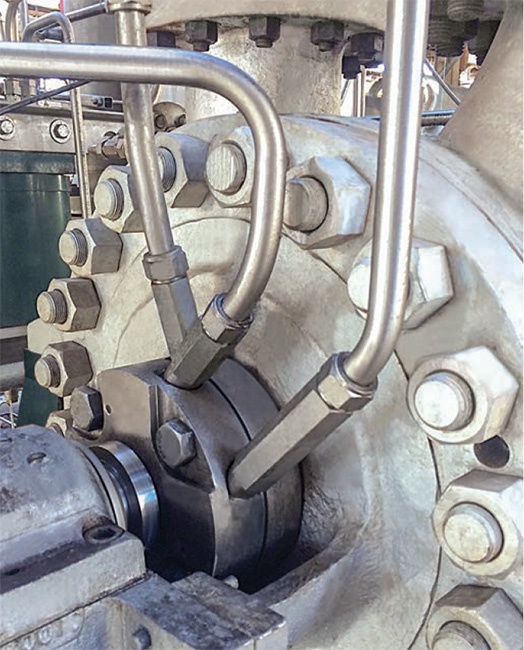

When tube fittings are intermixed or interchanged, it doesn’t matter, you are asking for trouble and we don’t recommend it! It is an unsafe business practice which could cause costly leaks, can lead to unpredictable performance and leave you vulnerable to hazardous safety and environmental conditions.

Can you live with costly leak? To learn more, view the Lowdown on Leakage infographic.

In this episode, Gary covers:

- Intermix/Interchange in the Field

- The Truth About Intermix/Interchange

- The Swagelok Performance Facts

- The Swagelok Warranty